Industry 4.0 & Smart Manufacturing

Turn data into decisions with secure, scalable Industry 4.0 infrastructure.

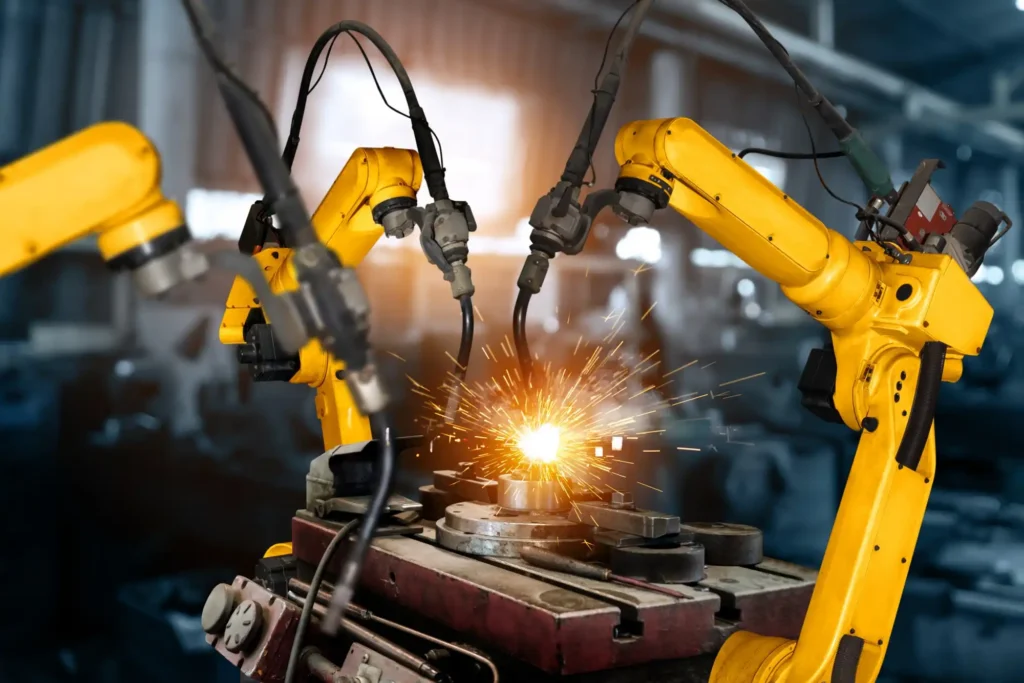

Modern operations require intelligent infrastructure to turn real-time machine data into actionable insights. At LHS, we empower factories, plants, and smart facilities with robust, scalable solutions that enable predictive maintenance, AI-driven monitoring, and seamless integration with existing SCADA, PLCs, and sensor systems. Whether you’re optimizing performance or enhancing security, our industry 4.0 ready solutions help you make smarter decisions faster.

Benefits Of Smart Manufacturing

Process real-time OT data at the edge

Integrate seamlessly with SCADA, PLCs, sensors

Enable predictive maintenance and AI-based monitoring

Built-in cybersecurity and multi-protocol compatibility

Use Cases Of Smart Manufacturing

From machine-level insights to enterprise-wide orchestration, our solutions deliver value across a wide range of Industry 4.0 initiatives:

- Machine Monitoring & OEE Insights

- Edge Processing for Predictive Maintenance

- Factory-wide Data Orchestration with Belden Horizon™

- Digital IO & IO-Link Sensor Integration

Solution Workflow

Our Industry 4.0 solution is designed for fast, scalable deployment and integration with your existing infrastructure

Step 1

Deploy DIN-rail edge gateways with Belden Horizon

Step 2

Connect PLCs, sensors, cameras via IO-Link, Profinet, etc.

Step 3

Process data locally or transmit to SCADA/cloud

Step 4

Visualize machine status and analytics in real time

Real Case Study

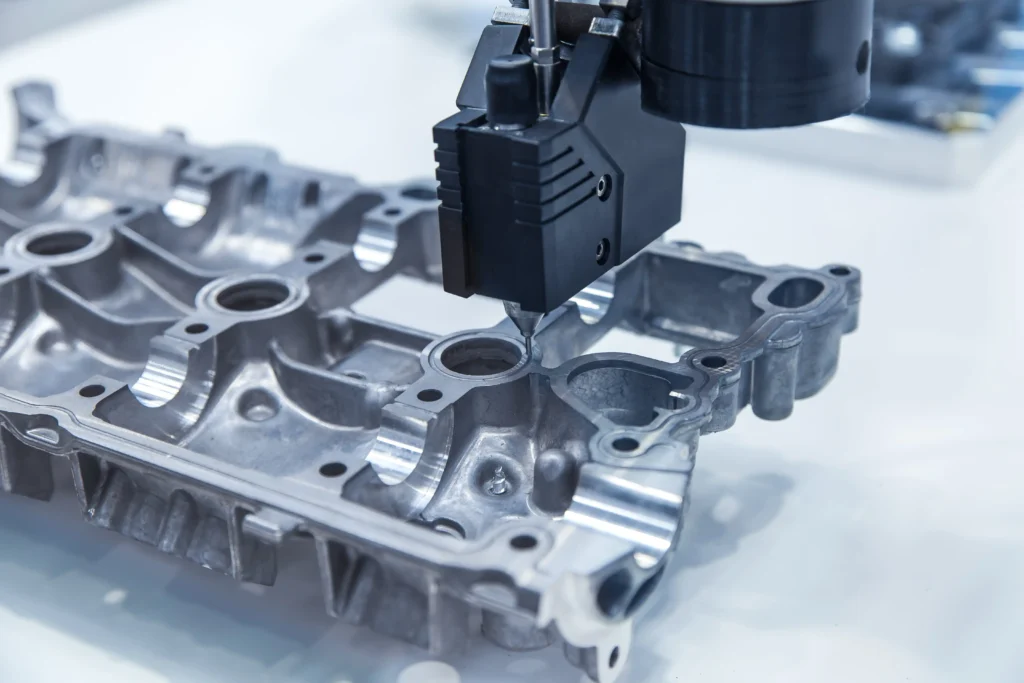

Global Automotive Leader — Predictive Maintenance Rollout

A leading vehicle manufacturer deployed industrial edge gateways to monitor vibration data from CNC machines. Data was processed locally, reducing unplanned maintenance downtime by 22% across 3 production sites.

Source: Belden Smart Manufacturing Use Case

https://www.belden.com/resources/case-studies/automotive-manufacturer-improves-efficiency-through-smart-manufacturing